BMA, BME series magnetic drive chemical process pump is our company based on the traditional ZA, ZE petrochemical process pump, concentrated on the development of a successful new magnetic drive chemical process pump, for the chemical process in the leakage pump system to provide a better choice.

The series of products adopt overall planning and design, serialization of spare parts, high degree of universality, making parts interchangeability is good. The hydraulic components are optimized by computer aided design with reference to excellent European hydraulic models. The structure is novel, the characteristic curve is hump-free, and the performance is stable. Pump anti-cavitation performance is good, compared with domestic similar products to reduce the installation height of about 25~30%, efficiency compared with similar products has also been greatly improved. The product is designed according to API685 standard, with high reliability and easy maintenance, which has unique advantages in the petrochemical industry.

Diameter: DN25~DN400

Flow rate: 5.5~800m3/h

Head: 8-200m

Temperature: -90 ℃~350 ℃

Pressure: 2-5MPa

Materials: 304, 316L, 2205, 904L, TC4, TA1, TA2, C-276, etc

Features: Compared with similar domestic products, it reduces installation height by about 25-30%, has good anti cavitation performance, and has unique advantages in the petrochemical industry

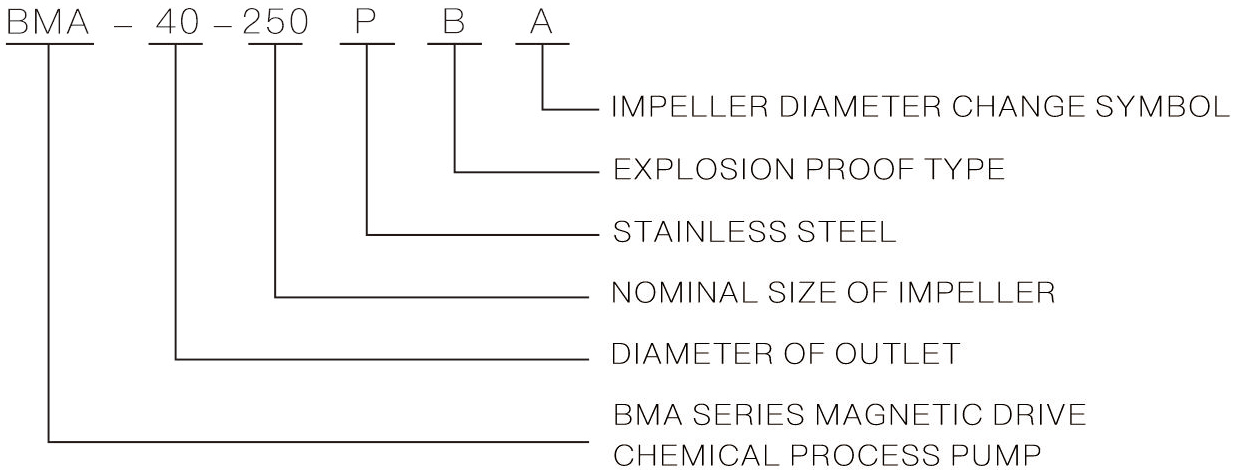

※ BMA series magnetic chemical process pump for the foot support chemical process pump.

※ BME series magnetic chemical process pump as the center to support chemical process pump.

Fully sealed, no leakage, no pollution;

CFD design hydraulic components, wide flow channel, high efficiency, good cavitation performance, small radial force;

The flow-through parts are made of fine casting mold and silicone sol medium temperature wax casting process. The size is accurate, the flow channel is fresh and clean, and the efficiency is high.

Process liquid self-cooling lubricating transmission parts, generally do not need additional piping system, engineering investment is small;

The whole pump only needs 1-2 sealing rings to ensure the best safety;

Low eddy current isolation sleeve design, pump efficiency is higher;

Direct motor or coupling structure can be selected;

Multi-circulation mode, self-circulation, auxiliary impeller forced circulation, auxiliary impeller pressure circulation and external circulation, etc., to meet the different conditions of medium transportation;

When the working conditions need to increase the cooling or heating insulation jacket structure;

There are two forms of foot installation and center line installation, which are used for different temperature media. The basic type adopts the foot support, and the high temperature type adopts the center support.

| Standard performance Table: | (Prime mover speed n=2900 r/min) | |||||||||||

| Type of pump | Inlet of suction diameter(mm) | Outlet of discharge diameter(mm) | Name of impeller diameter(mm) | Flow rate Q | Head of head H(m) | efficiency η(%) | Power of shaft (kW) | Cavitation allowance NPSHr(m) | Motor model Power (kW)& medium specific gravity (g/cm3) | |||

| m3/h | L/s | 1 | 1.35 | 1.84 | ||||||||

| BMA32-20-125 | 32 | 20 | 125 | 3.2 | 0.89 | 20 | 28 | 0.62 | 2.0 | 1.5 | 2.2 | 3 |

| BMA32-20-160 | 32 | 20 | 160 | 3.2 | 0.89 | 32 | 25 | 1.12 | 2.0 | 2.2 | 3 | 4 |

| BMA40-25-125 | 40 | 25 | 125 | 6.3 | 1.75 | 20 | 35 | 0.98 | 2.0 | 2.2 | 3 | 4 |

| BMA40-25-160 | 40 | 25 | 160 | 6.3 | 1.75 | 32 | 31 | 1.77 | 2.0 | 3 | 4 | 5.5 |

| BMA40-25-200 | 40 | 25 | 200 | 6.3 | 1.75 | 50 | 25 | 3.43 | 2.0 | 5.5 | 7.5 | 11 |

| BMA50-32-125 | 50 | 32 | 125 | 12.5 | 3.47 | 20 | 42 | 1.62 | 2.0 | 3 | 4 | 5.5 |

| BMA50-32-160 | 50 | 32 | 160 | 12.5 | 3.47 | 32 | 39 | 2.79 | 2.0 | 4 | 5.5 | 7.5 |

| BMA50-32-200 | 50 | 32 | 200 | 12.5 | 3.47 | 50 | 31 | 5.49 | 2.0 | 7.5 | 11 | 15 |

| BMA50-32-250 | 50 | 32 | 250 | 12.5 | 3.47 | 80 | 25 | 10.90 | 2.0 | 15 | 18.5 | 22 |

| BMA65-50-125 | 65 | 50 | 125 | 25 | 6.94 | 20 | 51 | 2.67 | 2.0 | 4 | 5.5 | 7.5 |

| BMA65-50-160 | 65 | 50 | 160 | 25 | 6.94 | 32 | 45 | 4.84 | 2.0 | 7.5 | 11 | 15 |

| BMA65-40-200 | 65 | 40 | 200 | 25 | 6.94 | 50 | 40 | 8.51 | 2.0 | 11 | 15 | 18.5 |

| BMA65-40-250 | 65 | 40 | 250 | 25 | 6.94 | 80 | 37 | 14.72 | 2.0 | 18.5 | 22 | 30 |

| BMA65-40-315 | 65 | 40 | 315 | 25 | 6.94 | 125 | 27 | 31.53 | 2.4 | 37 | 45 | 55 |

| BMA80-65-125 | 80 | 65 | 125 | 50 | 13.89 | 20 | 57 | 4.78 | 3.0 | 7.5 | 11 | 15 |

| BMA80-65-160 | 80 | 65 | 160 | 50 | 13.89 | 32 | 55 | 7.92 | 2.4 | 11 | 15 | 18.5 |

| BMA80-50-200 | 80 | 50 | 200 | 50 | 13.89 | 50 | 50 | 13.62 | 2.4 | 18.5 | 22 | 30 |

| BMA80-50-250 | 80 | 50 | 250 | 50 | 13.89 | 80 | 45 | 24.21 | 2.4 | 30 | 37 | 45 |

| BMA80-50-315 | 80 | 50 | 315 | 50 | 13.89 | 125 | 40 | 42.56 | 2.4 | 55 | 75 | 90 |

| BMA100-80-125 | 100 | 80 | 125 | 100 | 27.78 | 20 | 61 | 8.93 | 4.5 | 11 | 15 | 18.5 |

| BMA100-80-160 | 100 | 80 | 160 | 100 | 27.78 | 32 | 61 | 14.29 | 4.3 | 18.5 | 22 | 30 |

| BMA100-65-200 | 100 | 65 | 200 | 100 | 27.78 | 50 | 60 | 22.70 | 3.9 | 30 | 37 | 45 |

| BMA100-65-250 | 100 | 65 | 250 | 100 | 27.78 | 80 | 56 | 38.92 | 3.6 | 55 | 75 | 90 |

| BMA100-65-315 | 100 | 65 | 315 | 100 | 27.78 | 125 | 50 | 68.10 | 3.2 | 90 | 110 | 132 |

| BMA125-100-200 | 125 | 100 | 200 | 200 | 55.56 | 50 | 65 | 41.91 | 5.0 | 55 | 75 | 90 |

| BMA125-100-250 | 125 | 100 | 250 | 200 | 55.56 | 80 | 63 | 69.18 | 4.5 | 90 | 110 | 132 |

| BMA125-100-315 | 125 | 100 | 315 | 200 | 55.56 | 125 | 58 | 117.42 | 4.5 | 160 | 200 | 250 |

| Standard performance Table: | (Prime mover speed n=1450 r/min) | |||||||||||

| Type of pump | Inlet of suction | Outlet of discharge | Name of impeller | Flow rate Q | Head of head | efficiency | Power of shaft | Cavitation allowance | Motor model Power (kW)& medium specific gravity (g/cm3) | |||

| diameter(mm) | diameter(mm) | diameter(mm) | H(m) | η(%) | (kW) | NPSHr(m) | ||||||

| m3/h | L/s | 1 | 1.35 | 1.84 | ||||||||

| BMA 32-20-125 | 32 | 20 | 125 | 2 | 0.56 | 5 | 36 | 0.08 | 2 | 0.55 | 0.75 | 1.1 |

| BMA 32-20-160 | 32 | 20 | 160 | 2 | 0.56 | 8 | 33 | 0.13 | 2 | 0.55 | 0.75 | 1.1 |

| BMA 40-25-125 | 40 | 25 | 125 | 4 | 1.11 | 5 | 35 | 0.16 | 2 | 0.55 | 0.75 | 1.1 |

| BMA 40-25-160 | 40 | 25 | 160 | 4 | 1.11 | 8 | 32 | 0.27 | 2 | 0.75 | 1.1 | 1.5 |

| BMA 40-25-200 | 40 | 25 | 200 | 4 | 1.11 | 12.5 | 25 | 0.54 | 2 | 1.1 | 1.5 | 2.2 |

| BMA 50-32-125 | 50 | 32 | 125 | 6.3 | 1.75 | 5 | 34 | 0.25 | 2 | 0.55 | 0.75 | 1.1 |

| BMA 50-32-160 | 50 | 32 | 160 | 6.3 | 1.75 | 8 | 31 | 0.44 | 2 | 0.75 | 1.1 | 1.5 |

| BMA 50-32-200 | 50 | 32 | 200 | 6.3 | 1.75 | 12.5 | 24 | 0.89 | 2 | 1.5 | 2.2 | 3 |

| BMA 50-32-250 | 50 | 32 | 250 | 6.3 | 1.75 | 20 | 19 | 1.81 | 2 | 3 | 4 | 5.5 |

| BMA 65-50-125 | 65 | 50 | 125 | 12.5 | 3.47 | 5 | 41 | 0.42 | 2 | 0.75 | 1.1 | 1.5 |

| BMA 65-50-160 | 65 | 50 | 160 | 12.5 | 3.47 | 8 | 36 | 0.76 | 2 | 1.5 | 2.2 | 3 |

| BMA 65-40-200 | 65 | 40 | 200 | 12.5 | 3.47 | 12.5 | 31 | 1.37 | 2 | 2.2 | 3 | 4 |

| BMA 65-40-250 | 65 | 40 | 250 | 12.5 | 3.47 | 20 | 26 | 2.62 | 2 | 4 | 5.5 | 7.5 |

| BMA 65-40-315 | 65 | 40 | 315 | 12.5 | 3.47 | 32 | 21 | 5.19 | 2.5 | 7.5 | 11 | 15 |

| BMA 80-65-125 | 80 | 65 | 125 | 25 | 6.94 | 5 | 47 | 0.72 | 2.5 | 1.5 | 2.2 | 3 |

| BMA 80-65-160 | 80 | 65 | 160 | 25 | 6.94 | 8 | 45 | 1.21 | 2.5 | 2.2 | 3 | 4 |

| BMA 80-50-200 | 80 | 65 | 200 | 25 | 6.94 | 12.5 | 41 | 2.08 | 2.5 | 4 | 5.5 | 7.5 |

| BMA 80-50-250 | 80 | 65 | 250 | 25 | 6.94 | 20 | 37 | 3.68 | 2.5 | 5.5 | 7.5 | 11 |

| BMA 80-50-315 | 80 | 65 | 315 | 25 | 6.94 | 32 | 31 | 7.03 | 2.5 | 11 | 15 | 18.5 |

| BMA 100-80-125 | 100 | 80 | 125 | 50 | 13.89 | 5 | 55 | 1.24 | 2.5 | 2.2 | 3 | 4 |

| BMA 100-80-160 | 100 | 80 | 160 | 50 | 13.89 | 8 | 53 | 2.06 | 2.5 | 3 | 4 | 5.5 |

| BMA 100-65-200 | 100 | 80 | 200 | 50 | 13.89 | 12.5 | 51 | 3.34 | 2.5 | 5.5 | 7.5 | 11 |

| BMA 100-65-250 | 100 | 80 | 250 | 50 | 13.89 | 20 | 47 | 5.8 | 2.5 | 11 | 15 | 18.5 |

| BMA 100-65-315 | 100 | 80 | 315 | 50 | 13.89 | 32 | 43 | 10.14 | 2.5 | 15 | 18.5 | 22 |

| BMA 125-100-200 | 125 | 100 | 200 | 100 | 27.78 | 12.5 | 59 | 5.77 | 2.8 | 7.5 | 11 | 15 |

| BMA 125-100-250 | 125 | 100 | 250 | 100 | 27.78 | 20 | 53 | 10.28 | 2.8 | 15 | 18.5 | 22 |

| BMA 125-100-315 | 125 | 100 | 315 | 100 | 27.78 | 32 | 49 | 17.79 | 2.8 | 22 | 30 | 37 |

| BMA 125-100-400 | 125 | 100 | 400 | 100 | 27.78 | 50 | 43 | 31.68 | 2.8 | 37 | 45 | 55 |

| BMA 150-125-250 | 150 | 125 | 250 | 200 | 55.56 | 20 | 65 | 16.76 | 2.8 | 22 | 30 | 37 |

| BMA 150-125-315 | 150 | 125 | 315 | 200 | 55.56 | 32 | 63 | 27.67 | 2.8 | 37 | 45 | 55 |

| BMA 150-125-400 | 150 | 125 | 400 | 200 | 55.56 | 50 | 58 | 46.97 | 2.8 | 55 | 75 | 90 |

| BMA 200-150-250 | 200 | 150 | 250 | 400 | 111.11 | 20 | 67 | 32.53 | 3.2 | 45 | 55 | 75 |

| BMA 200-150-315 | 200 | 150 | 315 | 400 | 111.11 | 32 | 65 | 53.64 | 3.5 | 75 | 90 | 110 |

| BMA 200-150-400 | 200 | 150 | 400 | 400 | 111.11 | 50 | 63 | 86.48 | 3.8 | 110 | 132 | 160 |