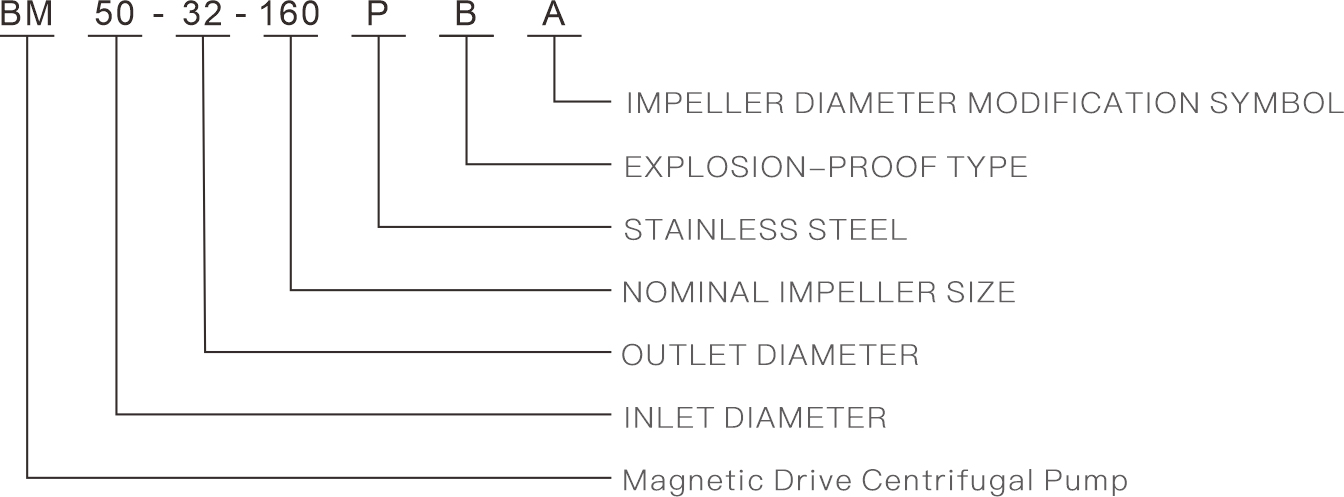

The BM series magnetic drive centrifugal pump has flow passage components primarily made of austenitic stainless steel. It is suitable for transporting liquids with a maximum pressure of 1.6 MPa, temperature not exceeding 120°C, and viscosity not greater than 30 mm²/s, without containing ferromagnetic particles and fibers. When the system pressure of the transported medium exceeds 1.6 MPa, the temperature exceeds 120°C, or when insulation measures are required, our company can provide special customization.

Diameter: DN32~DN200

Flow rate: 1.25~400m3/h

Head: 8-125m

Temperature: -90 ℃~120 ℃

Pressure: 0-1.6MPa (high-pressure~42MPa)

Power: 0.55kW~132kW

Materials: 304, 316L, 2205, 904L, TC4, TA1, TA2, C-276, etc

Fields: petroleum and petrochemicals, fine chemicals, pharmaceuticals, new energy, and other fields

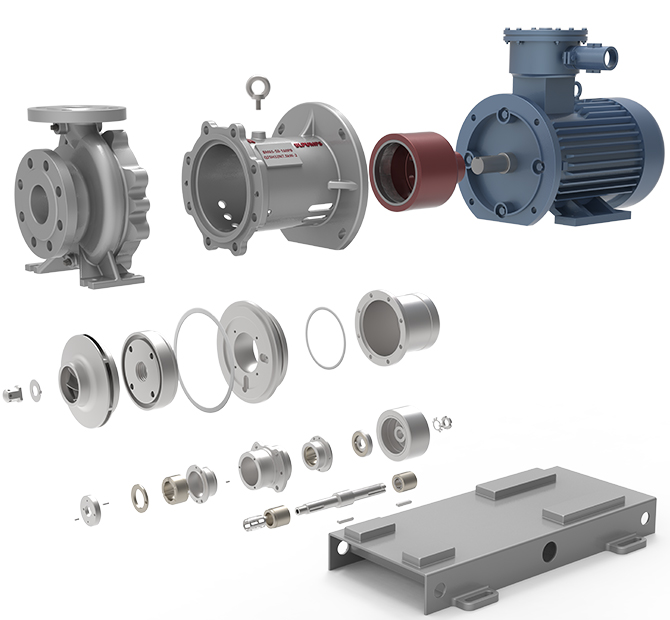

Fully sealed, no leakage, no pollution

CFD (Computational Fluid Dynamics) designed hydraulic components for wide flow channels, high efficiency, good cavitation performance, and low radial force

Flow passage components are precision-cast with silica sol medium wax casting technology for accurate dimensions and clean, smooth flow channels with high efficiency

Process liquid self-cools and lubricates the drive components, generally eliminating the need for additional piping systems, reducing project investment

Uses high-performance, high-temperature-resistant rare earth permanent magnet materials to ensure sufficient magnetic torque

Special magnetic circuit design with large magnetic gaps for industrial applications in some special products

Only 1-2 sealing rings required for the entire pump, ensuring optimal safety

Low eddy current isolation sleeve design for higher pump efficiency

Option for direct motor coupling or coupling structure

Direct motor coupling saves cost and space, has higher transmission efficiency, easy installation, and requires no alignment; for power above 37 kW, coupling connection is recommended for easier maintenance

Multiple circulation methods including self-circulation, auxiliary impeller forced circulation, auxiliary impeller pressurized circulation, and external circulation to meet different working conditions

Cooling or heating insulation jacket structure can be added if required by working conditions

Optional Y, YB series three-phase motors, DC motors, and permanent magnet motors

Optimized rigid shaft system design for better deflection index, reducing pump vibration, and extending the life of shaft system components

Two installation forms: foot-mounted and centerline-mounted for different temperature mediums, with the basic type using foot support and the high-temperature type using center support

Multiple flange standards such as ANSI, GB, HG available

Axial force floating balance structure design ensures that the axial force is fully balanced during pump operation; thrust bearings only bear axial thrust during pump start-up, resulting in almost zero wear during long-term operation

Shaft system components made of high-strength, highly corrosion-resistant materials with a dual bearing alignment structure and advanced fluid dynamic lubrication structure to ensure pump operational reliability and extend the life of shaft system components

Special lubrication and cooling design: circulation fluid carries away heat generated by eddy currents on the isolation sleeve and lubricates the sliding bearings, ensuring safe pump operation

| Standard performance Table: | (Prime mover speed n=2900 r/min) | |||||||||||

| Type of pump | Inlet of suction diameter(mm) | Outlet of discharge diameter(mm) | Name of impeller diameter(mm) | Flow rate Q | Head of head H(m) | efficiency η(%) | Power of shaft (kW) | Cavitation allowance NPSHr(m) | Motor model Power (kW)& medium specific gravity (g/cm3) | |||

| m3/h | L/s | 1 | 1.35 | 1.84 | ||||||||

| BM32-20-125 | 32 | 20 | 125 | 3.2 | 0.89 | 20 | 28 | 0.62 | 2.0 | 1.5 | 2.2 | 3 |

| BM32-20-160 | 32 | 20 | 160 | 3.2 | 0.89 | 32 | 25 | 1.12 | 2.0 | 2.2 | 3 | 4 |

| BM40-25-125 | 40 | 25 | 125 | 6.3 | 1.75 | 20 | 35 | 0.98 | 2.0 | 2.2 | 3 | 4 |

| BM40-25-160 | 40 | 25 | 160 | 6.3 | 1.75 | 32 | 31 | 1.77 | 2.0 | 3 | 4 | 5.5 |

| BM40-25-200 | 40 | 25 | 200 | 6.3 | 1.75 | 50 | 25 | 3.43 | 2.0 | 5.5 | 7.5 | 11 |

| BM50-32-125 | 50 | 32 | 125 | 12.5 | 3.47 | 20 | 42 | 1.62 | 2.0 | 3 | 4 | 5.5 |

| BM50-32-160 | 50 | 32 | 160 | 12.5 | 3.47 | 32 | 39 | 2.79 | 2.0 | 4 | 5.5 | 7.5 |

| BM50-32-200 | 50 | 32 | 200 | 12.5 | 3.47 | 50 | 31 | 5.49 | 2.0 | 7.5 | 11 | 15 |

| BM50-32-250 | 50 | 32 | 250 | 12.5 | 3.47 | 80 | 25 | 10.90 | 2.0 | 15 | 18.5 | 22 |

| BM65-50-125 | 65 | 50 | 125 | 25 | 6.94 | 20 | 51 | 2.67 | 2.0 | 4 | 5.5 | 7.5 |

| BM65-50-160 | 65 | 50 | 160 | 25 | 6.94 | 32 | 45 | 4.84 | 2.0 | 7.5 | 11 | 15 |

| BM65-40-200 | 65 | 40 | 200 | 25 | 6.94 | 50 | 40 | 8.51 | 2.0 | 11 | 15 | 18.5 |

| BM65-40-250 | 65 | 40 | 250 | 25 | 6.94 | 80 | 37 | 14.72 | 2.0 | 18.5 | 22 | 30 |

| BM65-40-315 | 65 | 40 | 315 | 25 | 6.94 | 125 | 27 | 31.53 | 2.4 | 37 | 45 | 55 |

| BM80-65-125 | 80 | 65 | 125 | 50 | 13.89 | 20 | 57 | 4.78 | 3.0 | 7.5 | 11 | 15 |

| BM80-65-160 | 80 | 65 | 160 | 50 | 13.89 | 32 | 55 | 7.92 | 2.4 | 11 | 15 | 18.5 |

| BM80-50-200 | 80 | 50 | 200 | 50 | 13.89 | 50 | 50 | 13.62 | 2.4 | 18.5 | 22 | 30 |

| BM80-50-250 | 80 | 50 | 250 | 50 | 13.89 | 80 | 45 | 24.21 | 2.4 | 30 | 37 | 45 |

| BM80-50-315 | 80 | 50 | 315 | 50 | 13.89 | 125 | 40 | 42.56 | 2.4 | 55 | 75 | 90 |

| BM100-80-125 | 100 | 80 | 125 | 100 | 27.78 | 20 | 61 | 8.93 | 4.5 | 11 | 15 | 18.5 |

| BM100-80-160 | 100 | 80 | 160 | 100 | 27.78 | 32 | 61 | 14.29 | 4.3 | 18.5 | 22 | 30 |

| BM100-65-200 | 100 | 65 | 200 | 100 | 27.78 | 50 | 60 | 22.70 | 3.9 | 30 | 37 | 45 |

| BM100-65-250 | 100 | 65 | 250 | 100 | 27.78 | 80 | 56 | 38.92 | 3.6 | 55 | 75 | 90 |

| BM100-65-315 | 100 | 65 | 315 | 100 | 27.78 | 125 | 50 | 68.10 | 3.2 | 90 | 110 | 132 |

| BM125-100-200 | 125 | 100 | 200 | 200 | 55.56 | 50 | 65 | 41.91 | 5.0 | 55 | 75 | 90 |

| BM125-100-250 | 125 | 100 | 250 | 200 | 55.56 | 80 | 63 | 69.18 | 4.5 | 90 | 110 | 132 |

| BM125-100-315 | 125 | 100 | 315 | 200 | 55.56 | 125 | 58 | 117.42 | 4.5 | 160 | 200 | 250 |

| Standard performance Table: | (Prime mover speed n=1450 r/min) | |||||||||||

| Type of pump | Inlet of suction | Outlet of discharge | Name of impeller | Flow rate Q | Head of head | efficiency | Power of shaft | Cavitation allowance | Motor model Power (kW)& medium specific gravity (g/cm3) | |||

| diameter(mm) | diameter(mm) | diameter(mm) | H(m) | η(%) | (kW) | NPSHr(m) | ||||||

| m3/h | L/s | 1 | 1.35 | 1.84 | ||||||||

| BM 32-20-125 | 32 | 20 | 125 | 2 | 0.56 | 5 | 36 | 0.08 | 2 | 0.55 | 0.75 | 1.1 |

| BM 32-20-160 | 32 | 20 | 160 | 2 | 0.56 | 8 | 33 | 0.13 | 2 | 0.55 | 0.75 | 1.1 |

| BM 40-25-125 | 40 | 25 | 125 | 4 | 1.11 | 5 | 35 | 0.16 | 2 | 0.55 | 0.75 | 1.1 |

| BM 40-25-160 | 40 | 25 | 160 | 4 | 1.11 | 8 | 32 | 0.27 | 2 | 0.75 | 1.1 | 1.5 |

| BM 40-25-200 | 40 | 25 | 200 | 4 | 1.11 | 12.5 | 25 | 0.54 | 2 | 1.1 | 1.5 | 2.2 |

| BM 50-32-125 | 50 | 32 | 125 | 6.3 | 1.75 | 5 | 34 | 0.25 | 2 | 0.55 | 0.75 | 1.1 |

| BM 50-32-160 | 50 | 32 | 160 | 6.3 | 1.75 | 8 | 31 | 0.44 | 2 | 0.75 | 1.1 | 1.5 |

| BM 50-32-200 | 50 | 32 | 200 | 6.3 | 1.75 | 12.5 | 24 | 0.89 | 2 | 1.5 | 2.2 | 3 |

| BM 50-32-250 | 50 | 32 | 250 | 6.3 | 1.75 | 20 | 19 | 1.81 | 2 | 3 | 4 | 5.5 |

| BM 65-50-125 | 65 | 50 | 125 | 12.5 | 3.47 | 5 | 41 | 0.42 | 2 | 0.75 | 1.1 | 1.5 |

| BM 65-50-160 | 65 | 50 | 160 | 12.5 | 3.47 | 8 | 36 | 0.76 | 2 | 1.5 | 2.2 | 3 |

| BM 65-40-200 | 65 | 40 | 200 | 12.5 | 3.47 | 12.5 | 31 | 1.37 | 2 | 2.2 | 3 | 4 |

| BM 65-40-250 | 65 | 40 | 250 | 12.5 | 3.47 | 20 | 26 | 2.62 | 2 | 4 | 5.5 | 7.5 |

| BM 65-40-315 | 65 | 40 | 315 | 12.5 | 3.47 | 32 | 21 | 5.19 | 2.5 | 7.5 | 11 | 15 |

| BM 80-65-125 | 80 | 65 | 125 | 25 | 6.94 | 5 | 47 | 0.72 | 2.5 | 1.5 | 2.2 | 3 |

| BM 80-65-160 | 80 | 65 | 160 | 25 | 6.94 | 8 | 45 | 1.21 | 2.5 | 2.2 | 3 | 4 |

| BM 80-50-200 | 80 | 65 | 200 | 25 | 6.94 | 12.5 | 41 | 2.08 | 2.5 | 4 | 5.5 | 7.5 |

| BM 80-50-250 | 80 | 65 | 250 | 25 | 6.94 | 20 | 37 | 3.68 | 2.5 | 5.5 | 7.5 | 11 |

| BM 80-50-315 | 80 | 65 | 315 | 25 | 6.94 | 32 | 31 | 7.03 | 2.5 | 11 | 15 | 18.5 |

| BM 100-80-125 | 100 | 80 | 125 | 50 | 13.89 | 5 | 55 | 1.24 | 2.5 | 2.2 | 3 | 4 |

| BM 100-80-160 | 100 | 80 | 160 | 50 | 13.89 | 8 | 53 | 2.06 | 2.5 | 3 | 4 | 5.5 |

| BM 100-65-200 | 100 | 80 | 200 | 50 | 13.89 | 12.5 | 51 | 3.34 | 2.5 | 5.5 | 7.5 | 11 |

| BM 100-65-250 | 100 | 80 | 250 | 50 | 13.89 | 20 | 47 | 5.8 | 2.5 | 11 | 15 | 18.5 |

| BM 100-65-315 | 100 | 80 | 315 | 50 | 13.89 | 32 | 43 | 10.14 | 2.5 | 15 | 18.5 | 22 |

| BM 125-100-200 | 125 | 100 | 200 | 100 | 27.78 | 12.5 | 59 | 5.77 | 2.8 | 7.5 | 11 | 15 |

| BM 125-100-250 | 125 | 100 | 250 | 100 | 27.78 | 20 | 53 | 10.28 | 2.8 | 15 | 18.5 | 22 |

| BM 125-100-315 | 125 | 100 | 315 | 100 | 27.78 | 32 | 49 | 17.79 | 2.8 | 22 | 30 | 37 |

| BM 125-100-400 | 125 | 100 | 400 | 100 | 27.78 | 50 | 43 | 31.68 | 2.8 | 37 | 45 | 55 |

| BM 150-125-250 | 150 | 125 | 250 | 200 | 55.56 | 20 | 65 | 16.76 | 2.8 | 22 | 30 | 37 |

| BM 150-125-315 | 150 | 125 | 315 | 200 | 55.56 | 32 | 63 | 27.67 | 2.8 | 37 | 45 | 55 |

| BM 150-125-400 | 150 | 125 | 400 | 200 | 55.56 | 50 | 58 | 46.97 | 2.8 | 55 | 75 | 90 |

| BM 200-150-250 | 200 | 150 | 250 | 400 | 111.11 | 20 | 67 | 32.53 | 3.2 | 45 | 55 | 75 |

| BM 200-150-315 | 200 | 150 | 315 | 400 | 111.11 | 32 | 65 | 53.64 | 3.5 | 75 | 90 | 110 |

| BM 200-150-400 | 200 | 150 | 400 | 400 | 111.11 | 50 | 63 | 86.48 | 3.8 | 110 | 132 | 160 |